Inventory planning and its optimization are extremely critical for businesses in diverse industries. The cost of carrying suboptimal inventory can have far reaching impact on the business and can completely saddle its bottom line. As a thumb rule, the inventory carrying costs of a business should be in the range of 20-30% of its total inventory cost. The derived business benefits from a well-planned and optimized inventory include:

- Preventing stock out situations and Inventory pile ups

- Reduce warehousing / storage costs

- Increased Gross Profit

- Resulting intime customer deliveries and improved service levels

Achieving these has never been easy! There have been multiple challenges businesses face and certain mistakes they make resulting in a mess up with their inventories. Often, Planning is run outside the ERP system even though all the inventory, order and planning parameters information is maintained inside the ERP. Applying this to the D365 Business Central NAV Services parlance, our consultants commonly come across one/many of following situations at customer sites.

- The knowledge to run and calculate MRP is with key people. As it’s a manual exercise it is generally dependent to these people’s knowledge. This knowledge and the tool used goes away along with such key person/s.

- Inappropriate or outdated Inventory classification and Planning parameter configuration is another challenge to overcome. This is a time taking and iterative exercise in practicality.

- Dynamic Business requirements & everchanging fluctuating Market situation – Seasonality of products adds to the challenges and complexities. The fact is there is no master configuration that fits to all the businesses and scenarios. However, there are best practices one can follow to achieve the goal

- Other common mistake seen is that a combined Inventory planning is run for complete organization and not by / for each separate location

- Most commonly, a single location is defined in the system for holding the ‘good’ and ‘rejected’ inventory, while it would be kept separate physically in the warehouse. This mistake results in inventory mix up and the planning results would be in correct

- Inventory planning is tricky for products ‘Custom’ made based on customer demand. However, the planning can still be done at the subassembly item level

- This is found to be one of the very common mistakes – Historical Sales and Purchase Orders still showing up open in the system. This creates a superficial demand and supply requirements and disturbs the whole planning process.

- Items with mixed replenishment (Produce and procure) method / policy Items bring another challenge. This can be overcome by creating 2 separate Items and defining one as the substitute of another.

The good news is that both Dynamics NAV and D365 Business Central have out of the box tools to run Inventory planning – Order Planning to run planning for special orders, Requisition planning for trading and retail industry for purchase Items and Planning Worksheet to be used by a manufacturing company to prepare MRP and MPS schedule.

The challenges and mistakes listed above are not easy problems to solve. The fact is Inventory planning is an iterative process and enough time should be assigned and devoted in configuring and tuning the system to the industry and business needs.

This blog covers the planning parameters and the related feature & functionality available in D365 Business Central for effective Inventory Planning. In addition to this, an important aspect is the Industry Best Practices one should follow for defining these planning parameters. Our next blog shall talk about the recommendations & Industry Best Practices for defining Reordering Policy and Planning Parameters in Dynamics NAV & D365 Business Central.

Below is an illustration of such an example and the steps on how Dynamics 365 Business Central can be configured for Inventory forecast and planning;

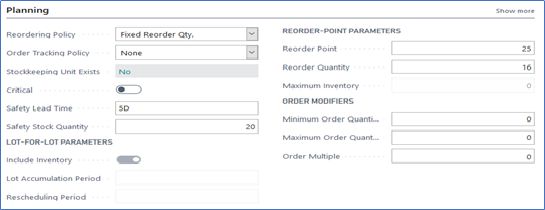

1. Setup: Replenishment method & Re-Ordering policy

2. Create: Stock Keeping Units for Location level planning

3. Define: Demand Forecast

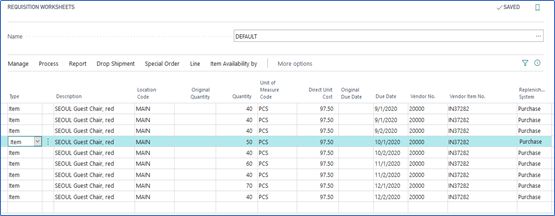

4. Run: Requisition Planning or MRP/MPS Planning for the demand forecast and create recommended Purchase Orders.

5. Impact of actual Sales Orders: the system is intelligent enough to take care and net off the demand forecast with the actual sales order received. In case the Sales Order is received for a higher quantity than forecasted, system shall suggest to procure more. You can also read the Inventory Planning and Optimization using D365BC/NAV – Part 2